Anyone can make a part or produce a product, but it’s an entirely different discussion to produce that piece repeatedly, with dimensional accuracy across the board from the first part all the way to the millionth. Manufacturing today operates in lock-step with the Quality Assurance team, especially in industries that demand absolute perfection in their products (ie. Automotive, Aerospace, Medical Devices, etc.) Here are just some of the attributes of a successful QA/Inspection technician:

CMM Machines – CMMs are pretty common for most QA facilities and are a highly automated way to inspect a large batch of components with minimal setup time involved.

3D Laser Scanners – Hand Scanners have come quite a long way over the last couple of years and have several utilities aside from just scanning. You can find these instruments used for doing reverse engineering, Quality Assurance checks, as well as helping to innovate an existing product.

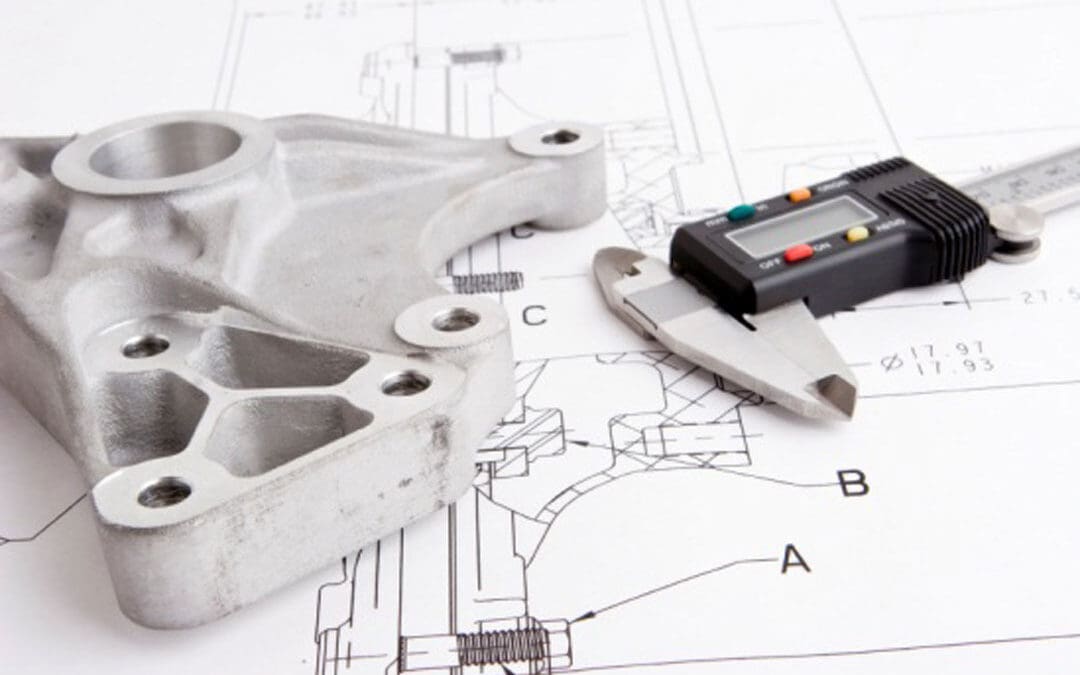

Hand Measurement Tools – Two of the most common ways to measure parts today are with a pair of Calipers or a Micrometer.

Micrometers – This hand tool is extremely precise, and is most commonly used to get exact measurements for round parts.

Calipers – Most commonly used for quick checks for dimensional accuracy, these mechanical tools can be used for a variety of checks including height, depth, distance, diameter, length, and more.

Again, the need for accurate and repeatable products has never been higher, especially for high-precision machine shops. Quality Assurance is a broad topic, spans all industries, and continues to be a high-demand career for the manufacturing industry. If you’re ever interested in learning what we teach in our Inspection Training program, check us out here.